If you are planning large-scale events or working on long-term installation that are expected to carry extreme loads, it is a good idea to think about using steel structures.

MILOS uses ultra-high-strength steel (UHSS) for the production of selected MILOS steel products.

Due to its high strength and toughness, UHSS is widely used in the automotive, mining, crane, and other highly specialized industries. The continuing development of UHSS makes it possible to design lighter and stronger structures for the most demanding conditions.

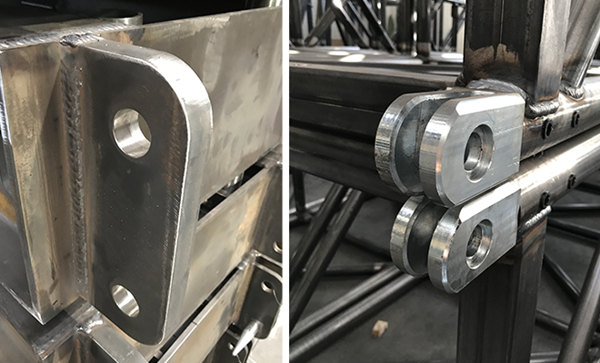

The preparation process for the actual welding is very important for high-quality and accurate welding. It goes without saying that the steel must be properly cleaned before the actual welding takes place. Additionally, the whole surface of the product needs to be treated so that the protective layer meets the strictest criteria for the life of the surface treatment.

Ambient temperature and surface treatment thus play an essential role in the welding process. The thickness of the welded material has an enormous impact on the welding itself. Thicker materials require multi-layer welding, which guarantees a solid connection of the welded components. Our highly qualified and skilled welders, who have successfully completed the full range of training necessary to produce work of such precision and expertise, weld MILOS steel structures using the MIG/MAG method. Thanks to our emplaced processes, production, and control mechanisms, we offer high-quality MILOS steel structures that meet the strictest criteria demanded by the current market trends and industry standards.

For more about MILOS steel truss products, please click

here.

MILOS. A 25+ years young brand, with fast, flexible, and affordable quality solutions.

“MILOS. Works Better”